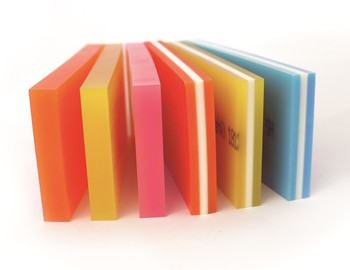

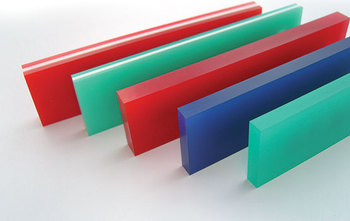

Squeegees

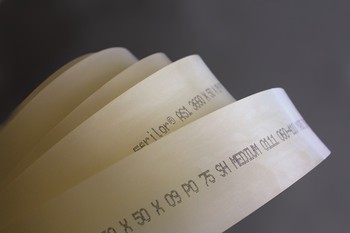

serilor®AS – ANTI-STATIC

A more conductive polyurethane used to reduce static problems in screen printing.

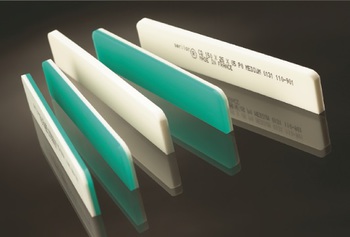

serilor®CD – OPTICAL MEDIA

For optical media printing, packed in convenient, ready-to-use, pre-cut sizes.

serilor®CERAM – EXTRA SOFT

High resistance squeegees in hardness from 35 to 55sh for the direct printing of ceramics.

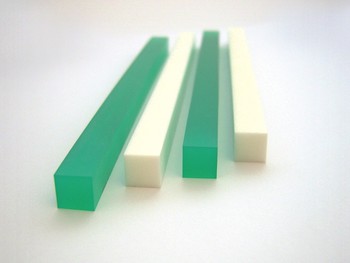

serilor®D – SQUARE PROFILE

For high precision screen printing applications such as PCBs, solar panels, CD’s…

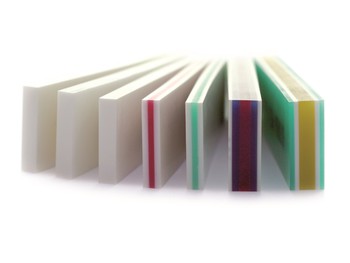

serilor®HR – HIGH RESISTANCE

For use with industrial and UV inks that require maximum abrasion and chemical resistance.

serilor®LC – BEST VALUE GRADE

For all non-critical applications, from textile to multi-purpose graphic printing.

serilor®SR – UNIVERSAL USE

Your ideal choice for all purpose printing, combining good resistance to chemicals and abrasion.